Shaking Up Electrification

Aristeo is at the forefront of automotive innovation by building, renovating and expanding facilities for electrification. Recently, we completed an expansion to Ford Motor Company’s Research & Engineering campus with an addition to Building #4 in Dearborn, MI. Building #4 drives electrification research as it houses one of the world’s largest shaker tables for EV battery research. Aristeo managed the two-story expansion, and also self performed earthwork, concrete, steel fabrication and steel erection services.

Precision Techniques

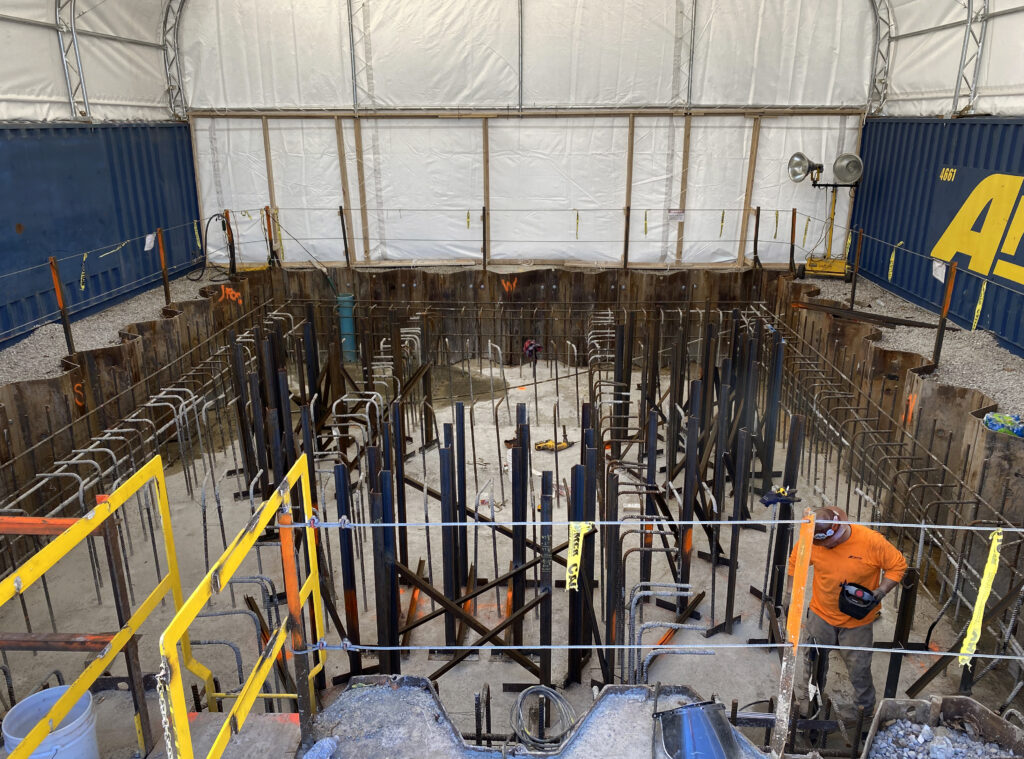

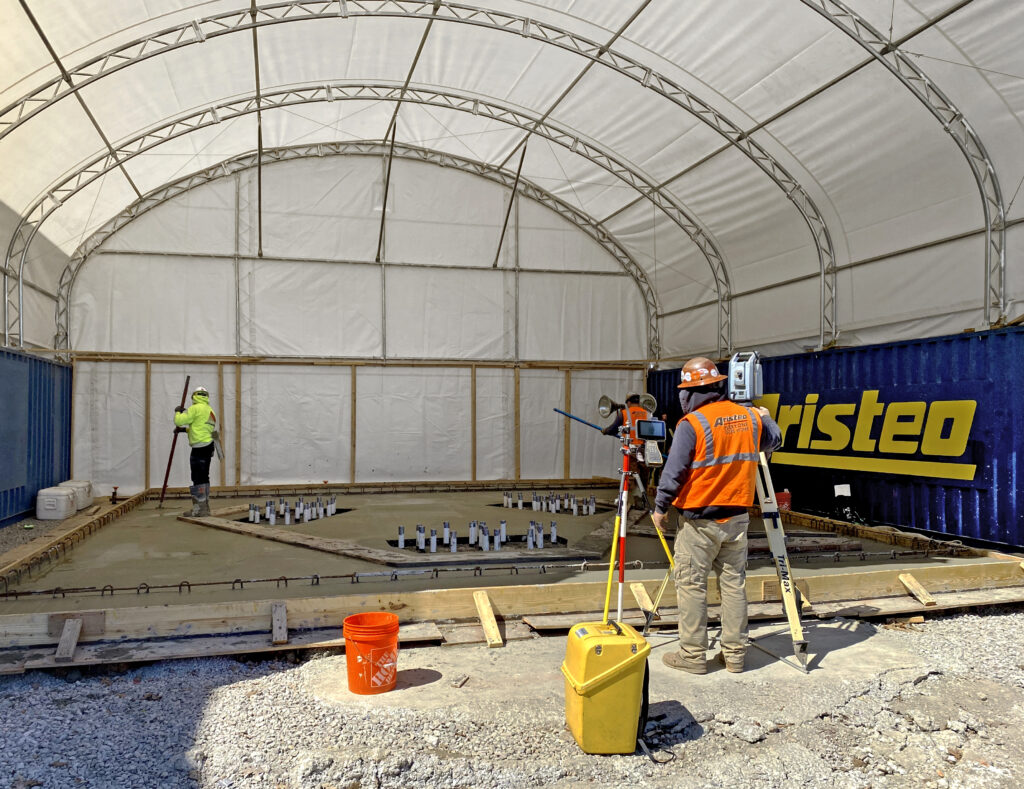

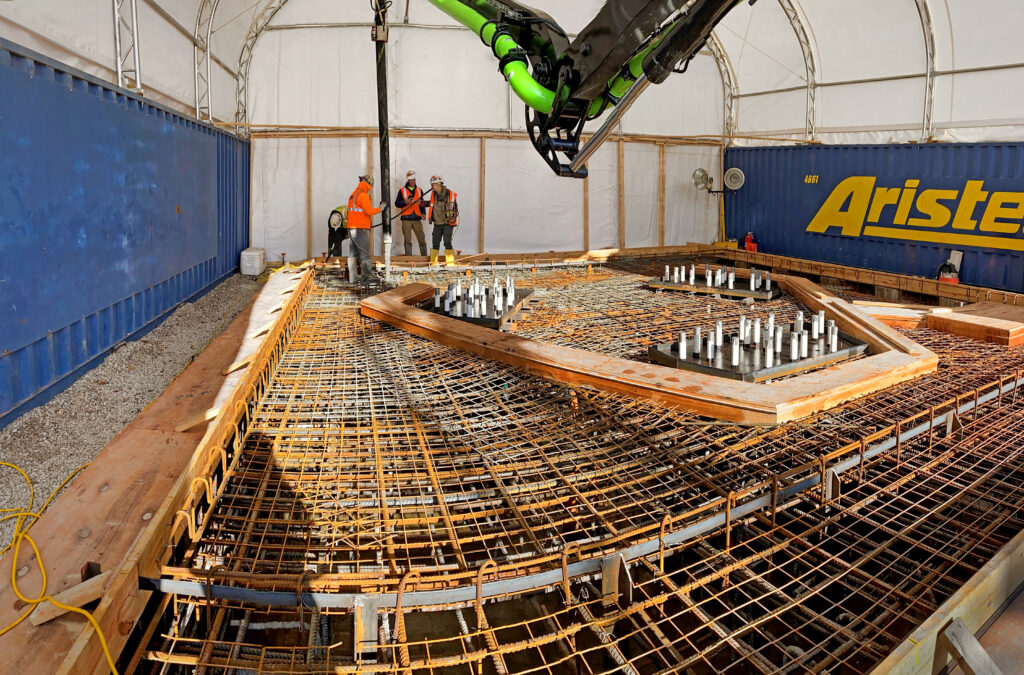

A shaker table is a large piece of equipment that shakes a battery during the research and testing phase. Technical concrete expertise was imperative to the success of this project since the shaker table foundations required 1/16th of an inch precision. The deep mass foundation was placed with three depressions, each with 19 anchor bolts to secure the three legs of the shaker table. Each anchor bolt had an anchor plate embedded into the concrete, which required a custom anchor bolt design to allow staggering in the tight bedplate area.

The sheer size of the mass foundation and tolerances needed for the shaker table required the team to follow strict guidelines and sequencing. Because the pour took place in the winter, we utilized heaters, concrete blankets for insulation, sensors and a temporary structure to regulate the temperature. This required manpower on site seven days a week to meet with inspectors taking temperature readings and to keep the heater running.

Unique Technology

Vigorously shaking batteries for testing can cause scenarios that require precision safety equipment. A durable, high performance translucent wall panel system was installed to provide a unique look for the addition and an additional element of safety. We installed the panels to shift the upper exterior of the building to reduce damage in the event of an explosion. Another unique element of this project is an expansive gas detection system with monitoring tied to an alarm system. The alarm system is comprised of a fire extinguishing system and thermal detection cameras, which also have the capability to record the testing.

Aristeo Adapts

This site is located on the busy Ford Dearborn R&E campus, requiring special care to reduce noise and disturbances. We reduced vibrations made while installing the earth retention system by utilizing unique machinery to minimize distractions to the active, adjacent testing facility. We also closely coordinated with our subcontractors for deliveries and equipment storage during construction due to the limited laydown area. Thanks to our decades of experience and success in similar projects, we completed this project with zero incidents across nearly 10,000 manhours.